15.05.2023

Mettler-Toledo Launches X2 Series of X-ray Solutions

Mettler-Toledo Product Inspection has launched the X2 Series of high-performing x-ray systems to help enhance product safety for all food manufacturers. With two x-ray systems currently in the X2 Series, x-ray inspection is now accessible for all budgets, offering manufacturers software that is designed to last longer and perform better.

The creative design of the X2 Series helps enhance brand protection and product safety while also increasing product quality. Helping manufacturers to meet food safety compliance requirements, while also offering enhanced productivity, the X2 Series, delivers outstanding reliability with a smart industrial design.

The X2 Series helps prevent product recalls through its contamination detection capabilities. The x-ray inspection technology inspects a wide range of contaminants, including glass, metal, mineral stone, calcified bone, dense plastic and rubber compounds whilst simultaneously completing a number of quality control and integrity checks. The X2 Series offers significant benefits both in-line and at end-of-line inspection by using innovative technology all designed for optimum performance and output.

The company’s ContamPlus software is an inspection process which scans products for every kind of contaminant and not just the ones optimised during the initial automatic product set-up. The automatic set-up detects the most hard-to-find foreign bodies and rejects only the contaminated products, reducing production waste and protecting productivity. This is especially crucial for food manufacturers, where product integrity and completeness is key as missing information or products can lead to costly recalls and, sometimes dangerous, results.

At the heart of the design is a new product inspection chamber and a modular mechanical design which allows full frontal access to all the most common operations. It offers a range of new features to improve operations such as product handling, cleaning and service routines. The X2 Series’ range of standard length and height configurations is complemented by bespoke designs to allow total customisation to meet exact customer needs.

Food manufacturers can reduce cleaning output and maintenance routines as well as the need for complex operator training with the X2 Series’ front-opening hygienic design. Designed for efficient cleaning, the solution makes it easy for operators to perform regular maintenance routines. The conveyor belt can be removed swiftly and without tools by releasing the tension with the handle situated on the infeed roller. The lead-free, low friction curtains also allow smooth product transition through the machine, with the presence of curtains constantly monitored to help keep the operator safe.

Manufactured in Europe, the X2 Series consists of two models – the X12 and X32, both are available in multiple line configurations 800, 1300, 1800 and 2000 mm line lengths.

The Mettler X2 1300

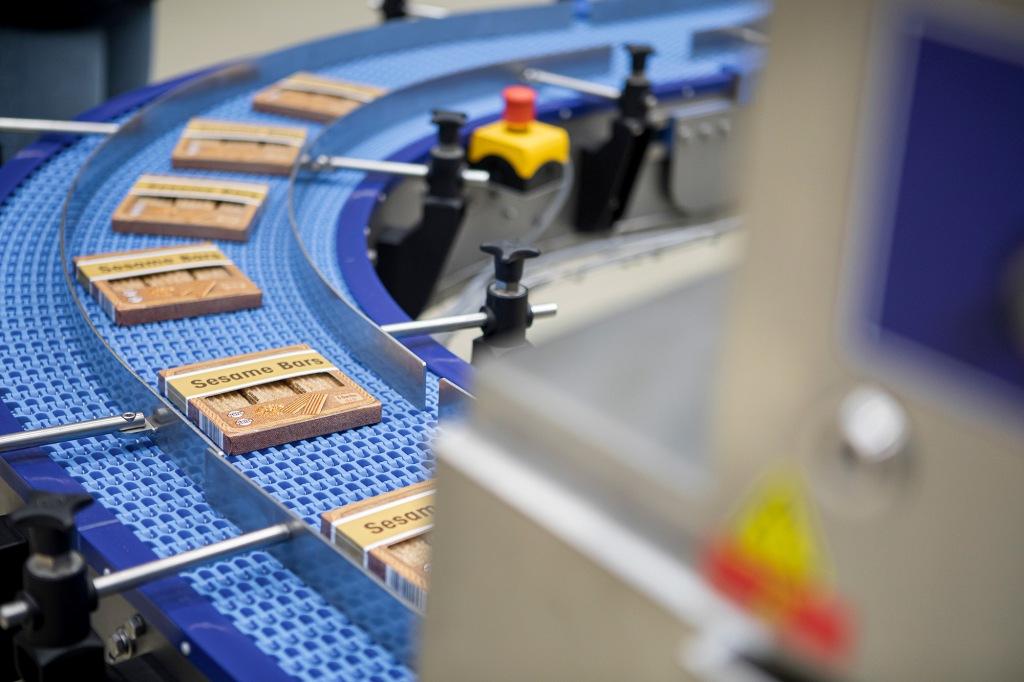

(Middle) Sesame Bar Production

(Bottom) Intuitive User Interfacec

« Back

|