23.01.2023

Minimising ferrous contamination for the food industry

Due to their very high strength, Rare Earth magnets are seen as critically important process equipment in the food industry. They can extract ferrous contamination as small as 30 microns, (much smaller than the calibration of metal detectors). Consequently, they are considered to be an additional control mechanism to metal detectors - which are used as a final check at the end of the process line.

Magnetic separators are most commonly used in the primary (raw material intake) and secondary (production) processes to remove any extraneous ferrous contamination as quickly as possible, to ensure clean product flow as well as reducing the risk of costly machinery damage. These systems can also remove metal entering the production line as a result of equipment failure.

Bespoke Solutions Worldwide

Given the enormous variation in manufacturing systems and processes across such a diverse range of sectors, it can be difficult to install a ‘standard’ magnetic separator into a production line. Separators need to be designed to fit into a specific pipeline, conveyor, or hopper.

Greenwood Magnetics has been designing and manufacturing bespoke magnetic separators for over 70 years for a wide range of industries, but with specific expertise is the food industry.

“Easy Clean”

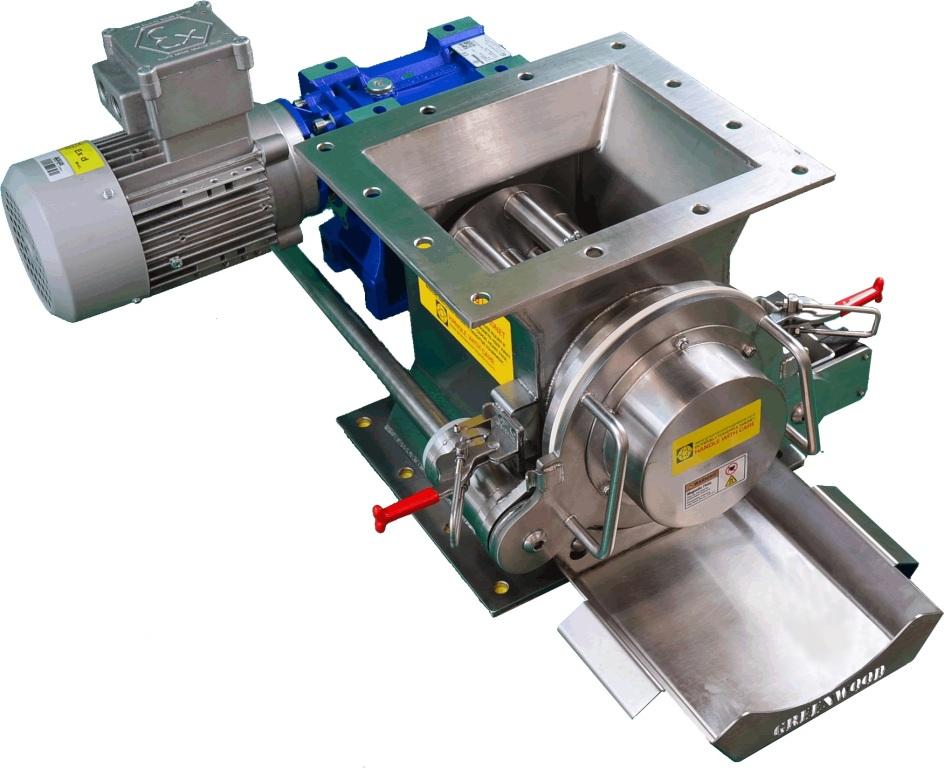

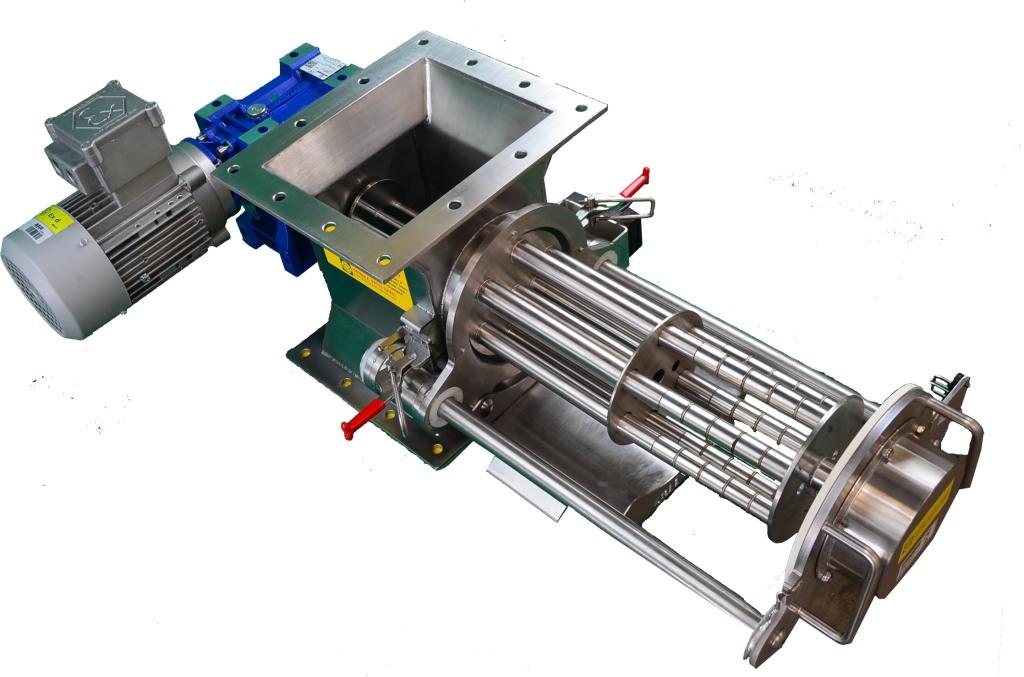

As part of the company’s R & D work to develop new solutions to meet the specific needs of our customers, a recent development is the “Greenwood Easy Clean Rotary magnet” approved and certified by Intertek (Notified Body number 0359) for use in ATEX Zone 20 internal environments delivering magnetic strength of 10000 Gauss at the contact face. This is typically used for products that tend to bridge such as milk powder or starch.

As they need to be cleaned regularly to maintain efficiency, the easy clean facility makes this job much simpler and faster for the operatives, reducing downtime. It also improves operator health and safety by reducing the risk of cuts and abrasions which could possibly occur from removing sharp metal fragments from the powerful internal magnet.

Certified Gauss Testing

Magnetic separators are now deemed so important that companies audited by the British Retail Consortium (BRC) are required to test and document their magnets on a regular basis.

This can include procedures for the inspection, cleaning, strength testing and integrity of magnetic separators. Given the stringent requirements in the food industry, 7000 gauss on the contact surface of the magnets is now set as the bare minimum magnetic strength acceptable for secondary stage process and critical control points.

www.greenwoodmagnetics.com

Greenwood Rotary Magnet – Easy-Clean technology, 10000 gauss, ATEX Zone 20 certified

Gauss Test underway

« Back

|