|

|

|

|

| News |

09.01.2023

Re-designed FSC agitator offers improved operator access

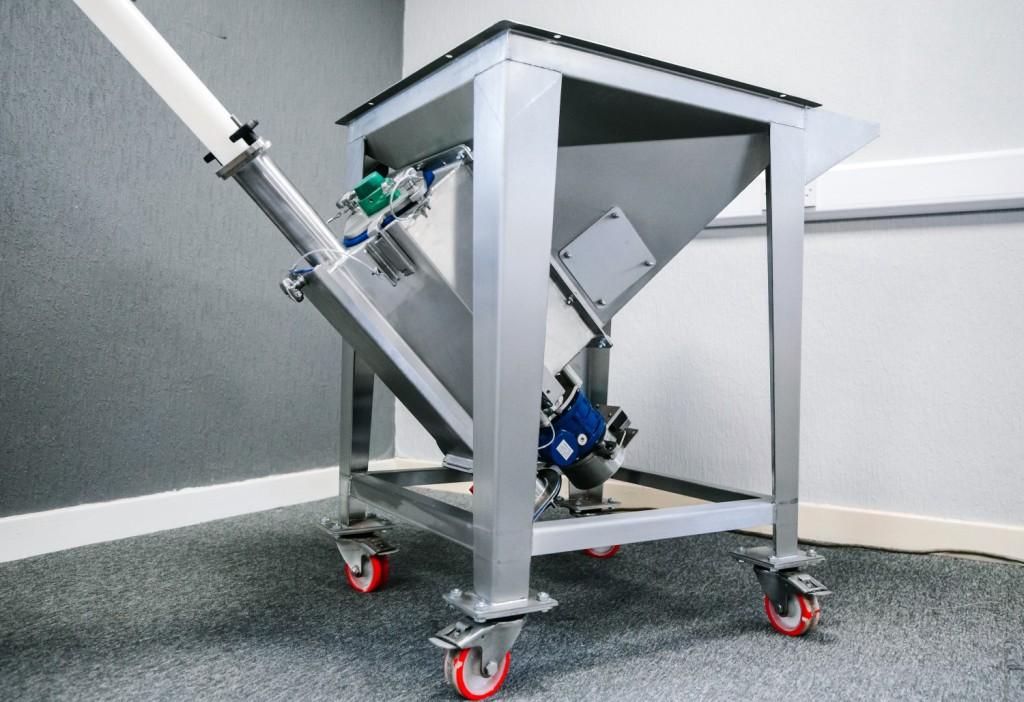

Powder handling and dry bulk solids processing specialist, Spiroflow, has re-designed its existing Flexible Screw Conveyor (FSC) agitator with an updated version which can be dismantled in place for cleaning. The new design can also be retrofitted to existing machines in place of the current standard agitator unit.

Used to ensure a consistent flow of product, the agitator can be fitted as an optional extra on Spiroflow FSCs when needed and used to break down bridging material in the flexible screw inlet. Many products being conveyed are not free-flowing, so the agitator helps to create material flow within the equipment. Spiroflow’s standard agitator design has been in use for over 20 years and required the use of tooled intervention to remove it and take it apart; the new version can be easily stripped down and reassembled in situ safely as required.

“In certain situations, it’s important for our customers to have the ability to quickly strip down the agitator to be cleaned by the operator safely, and without the use of tools,” said Spiroflow’s Chris Brennan, technical sales manager. “With the new agitator design, all access is protected by safety interlocks and the gearbox and motor remain in place. There is no need to have plugs and sockets or heavy lifting to facilitate its removal, so cleaning to be done on the line, thereby saving time in the process. The additional benefit of the new agitator is that it can be retrofitted to existing FSCs.”

www.spiroflow.com

Spiroflow’s re-designed Flexible Screw Conveyor agitator

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|