22.02.2021

Assess, prevent, predict – saving money and energy

Gericke, Regensdorf, Switzerland, reports that with its extensive experience not only in powder processing but also automation and sensor integration, its systems allow for online access to sensors and analytics as well as direct diagnostics to assess the process and machine and associated maintenance planning.

With sensors and fieldbus technology widely available, a process and its equipment can be monitored in many ways. A key expertise of the machine and system supplier is to know what data needs to be collected and analysed. A good example is dense phase conveying. Gericke is a leading supplier of this technology, which by design already saves energy and air. By applying the right combination of sensors and control algorithms, the company can better monitor the state of the conveying process. This allows for further optimisation while running the system or scheduling preventive maintenance if process parameters imply a potential change of conditions. With Gericke’s IoT (Internet of Things) capability, this information can be accessed and evaluated from any location, and a service intervention scheduled before a process stops.

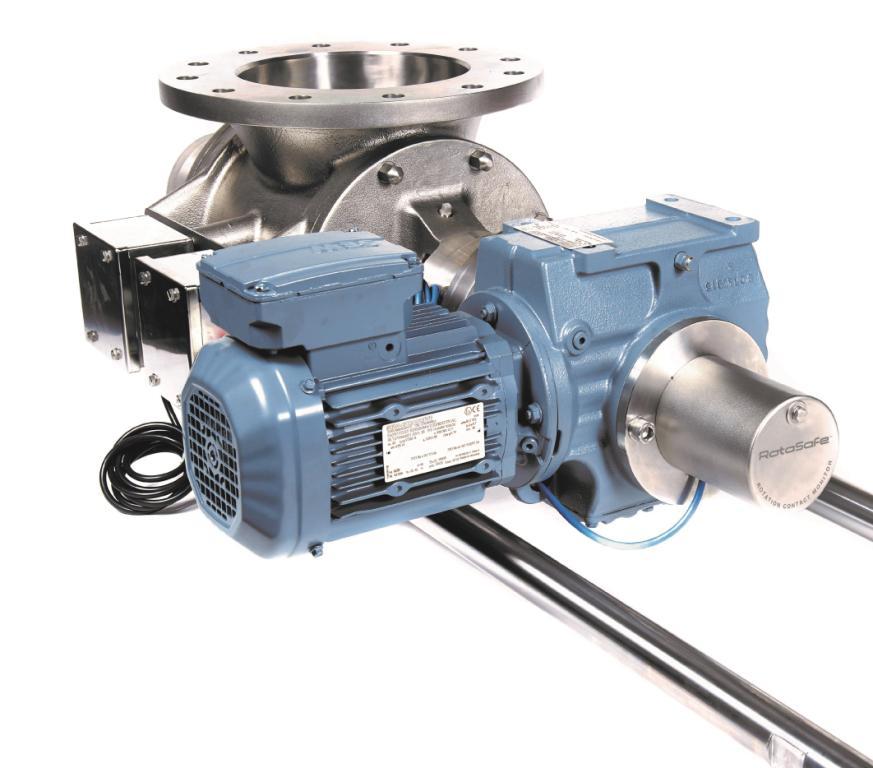

Many machines used in powder processing and handling contain moving parts, mostly made of metals. Metal-to-metal contact of such parts can be avoided to a wide extent by applying a high level of production standards and quality checks. However, this cannot prevent all cases where metal contact in a running machine can lead to damage or, even worse, to undetected metal parts contaminating the product. Gericke applies its many years of experience in detecting metal to metal contact in rotary valves (RotaSafe), and introduces this technology to other equipment with rotating parts, such as feeders and de-agglomerators. The diagnostic information can be processed with any automation systems and accessed remotely.

All the data monitored and collected only makes sense if is it processed and applied as part of a sophisticated automation concept. Gericke’s new controller family connects the specific expertise used for powder processing to the PLC, MES and ERP network of a customer. The full modularity and access to all common communication protocols allows for integration into any automation architecture, including local WLAN or fully remote access, while maintaining all IT security standards. www.gerickegroup.com

Gericke’s GUC modular controller

RotaSafe rotation contact monitor from Gericke

« Back

|