|

|

|

|

| News |

22.04.2024

Celebrating 50 years of air cannon technology

Martin Engineering is marking the 50th anniversary of its invention of its low-pressure air cannon.

Air cannons have transformed material flows in bulk processing systems, eliminating problematic internal buildups and blockages.

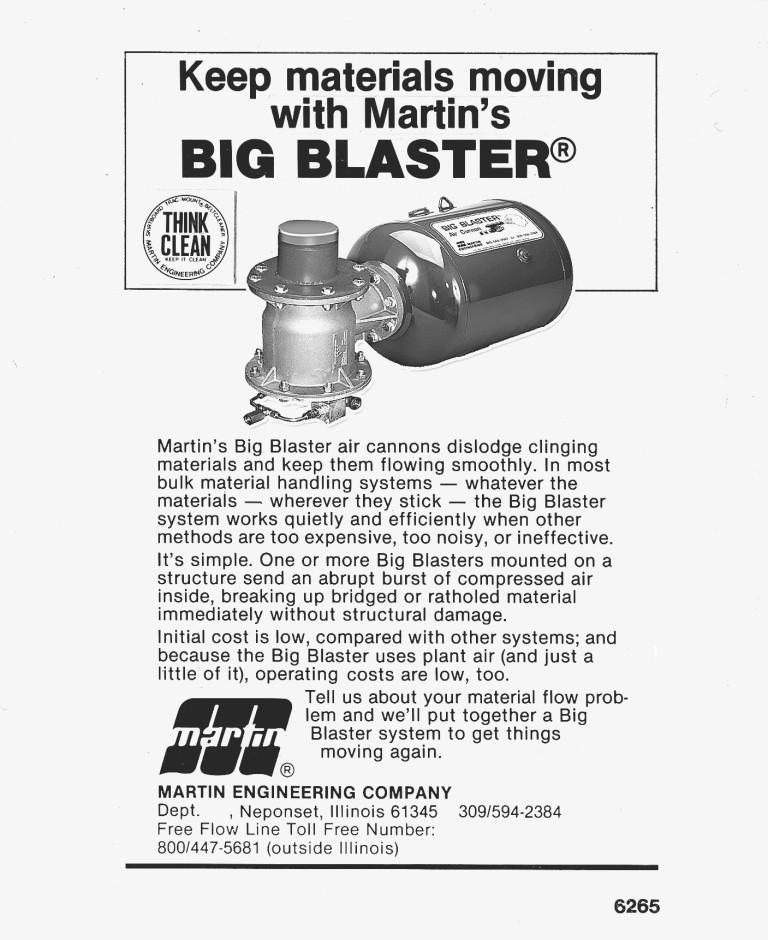

The company launched the “Big Blaster” air cannon in 1974. It was devised and developed by Carl Matson, a member of Martin’s senior team and cousin of the firm’s founder Edwin F. Peterson.

The patented technology was designed to dislodge stubborn material stuck to the inside walls of hoppers and silos by firing precisely timed bursts of compressed air to keep bulk material flowing and preventing the growth of serious build-ups and blockages.

The air cannon was originally aimed at the same quarrying applications as the Vibrolator, the Martin-patented industrial ball vibrator on which the company’s success had been built since its inception in 1944.

By the 1980s, as Martin Engineering expanded its global presence, the Big Blaster was already being reimagined for use in high-temperature industrial applications to maintain the flow of sticky materials through the process and minimise unscheduled downtime.

Martin air cannons soon proved themselves in sectors such as cement, for the first time signalling an end to workers having to access the interior of preheater vessels to manually break off hefty material build-ups using a high pressure water jet – one of the most unpleasant and hazardous jobs on a cement plant.

By the 1990s Martin Engineering had developed an extreme heat and velocity version of the Big Blaster, the XHV, with an all-metal construction capable of withstanding the harshest of conditions. In the 2000s Martin became the first to introduce safer positive-pressure firing valve with its Tornado air cannon – technology that prevents unintentional firing if there’s a drop in system pressure, and also allows solenoid valves to be positioned up to 60m (200 ft) from the air cannon for easier access and maintenance. Designed with safety in mind, the positive firing valve also delivers a more powerful blast.

Soon after that came the introduction of the Hurricane valve, located in the rear of the air cannon tank rather at the tank and nozzle junction, greatly improving safety and ease of maintenance. The exterior-facing design eliminates the need for removal of the tank so maintenance is a simple one-worker operation requiring only minutes for replacement.

In 2008, Martin Engineering opened its Center for Innovation, which accelerated the company’s air cannon technology advancements including SMART Series Nozzles with multiple nozzle tips and the Martin® Thermo Safety Shield acts as a safety barrier to allow maintenance of air cannon systems. It protects workers from exposure to severe temperatures so that maintenance can take place safely and production stays on schedule.

The Center for Innovation is located at the company’s headquarters in Neponset, Illinois. The center will open its doors to visitors in the Summer of 2024 as part of the 50th anniversary celebrations.

www.martin-eng.com.

(Top) Martin Engineering Business Development Manager Mike Masterson and Product Manager Sid Dev working at the Air Cannon test stand at the company’s Center for Innovation.

(Middle) Air Cannons like Martin’s Hurricane are in widespread use around the world in industries such as cement, steel, lime, coal, biomass, fertilizer and more.

(Bottom) An original display ad for Martin’s Big Blaster air cannon.

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|