15.04.2024

Optimising crushing at Dachser

Building materials supplier Dachser is currently expanding and optimizing its gravel plant in Türkheim by integrating a second rotor impact mill of type RPM 1113 from BHS-Sonthofen. In addition, BHS supplied the complete control system to ensure seamless coordination of the two machines. This makes the plant easier to operate and also increases productivity and efficiency.

For more than 60 years, Dachser has been supplying numerous construction projects with building materials such as ready-mixed concrete, sand, and gravel. At its Türkheim site, the company's own gravel plant produces high-quality sand with a grain size of 0-4 millimeters for concrete production from excess gravel. “Since we blend the crushed sand with natural sand, the resulting grain shape must be as close as possible to that of natural sand,” explains Michael Zacher, Head of Technology at Dachser. Previously, this task was accomplished using rod mills. However, these proved to be energy-intensive at low throughput rates.

Since 2019, a rotor impact mill of type RPM 1513 from BHS-Sonthofen has been crushing the material to the required fine particle size. This high-performance vertical shaft impact mill, which is employed by Dachser in a customized configuration, is particularly suitable for crushing all low to medium-abrasive minerals.

To keep up with growing market demand, the company decided to further expand its plant in early 2023. Based on the positive experience with BHS-Sonthofen, they decided to replace the remaining, outdated rod mill with a new BHS rotor impact mill. In the case of the RPM 1113, Dachser opted for a bottom-mounted drive for easier maintenance access and a modified, elevated machine housing with optimized flow performance. In close cooperation with Dachser, BHS carried out the project and commissioned the machine in the spring of 2023.

This particular machine's housing is a special version of the standard model with two enlarged openings in the discharge area, which allow for faster discharge of both crushed material and air. A downward-facing flanged motor was installed to provide more space for operation on the platform. The functionality of the RPM 1113 enables significantly higher throughput while consuming less energy compared to the rod mill.

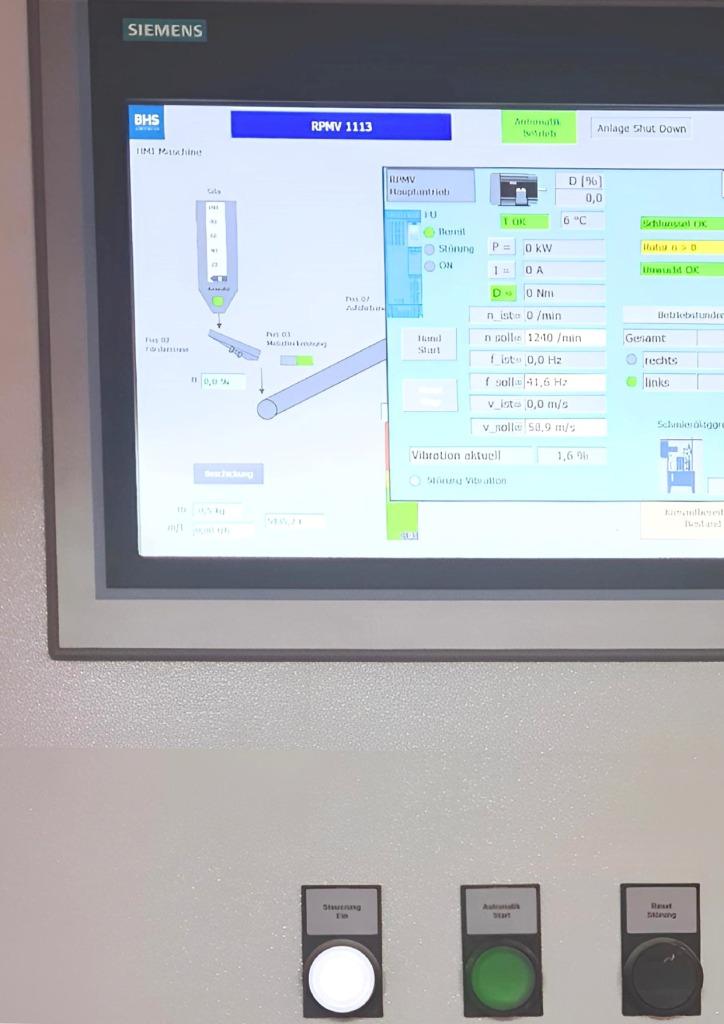

BHS-Sonthofen also provided the complete control system for the two rotor impact mills and the corresponding environment, customized specifically for Dachser’s needs. This includes powerful frequency converters for energy-efficient operation of the machines and a state-of-the-art user interface featuring touch screens. “Despite different feed materials, both machines deliver identical, high-quality crushed sand, something that is particularly sought after,” says Michael Zacher, summarizing the advantages of the two plants. “Having both the plant and control system from a single source, i.e. from BHS-Sonthofen, streamlined installation and daily operations significantly.”

www.bhs-sonthofen.com/en

(Top) Since 2019, Dachser has been using BHS rotor impact mill type RPM 1513 to produce sand from excess gravel

(Second) The alternating direction of rotation of the Rotor Impact Mill ensures uniform wear across all components, reducing system maintenance requirements.

(Third) BHS-Sonthofen not only provided the machine, but also the control solution for the entire system.

(Fourth) The control system features powerful frequency converters for energy-efficient operation of the machines and a modern user interface with touch screens.

« Back

|