15.04.2024

Screw conveyor enhances handling at Johnson Matthey

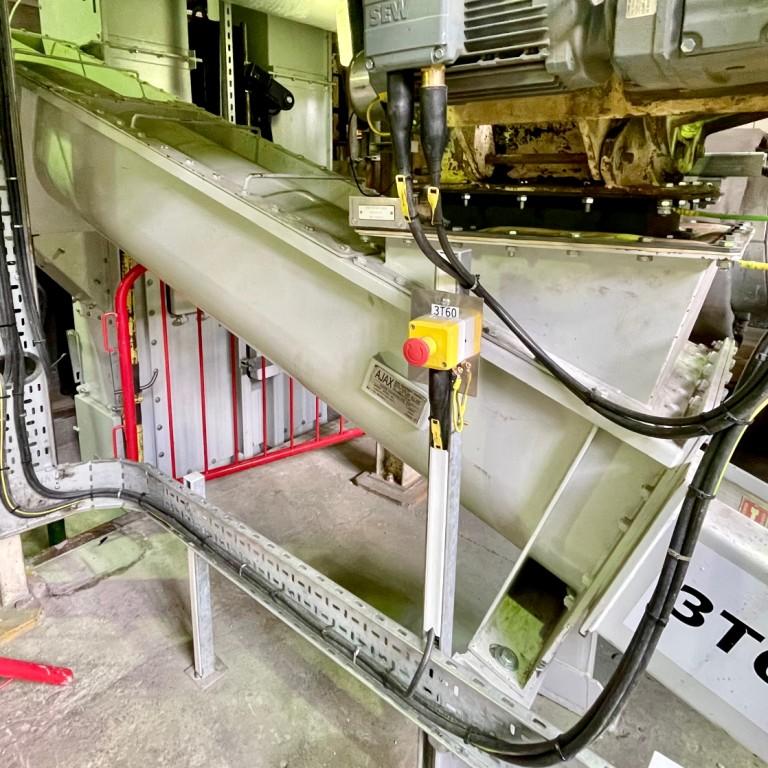

Solids handling equipment specialist, Ajax Equipment, has supplied speciality chemicals and sustainable technologies company, Johnson Matthey, with an inclined screw conveyor and chute sections to enhance the handling of a catalyst material at temperature.

Since the screw conveyor is operating at an incline, the machine includes a range of features to ensure effective material transfer and mitigate any material fall back. The conveyor’s flights were manufactured in a smooth finish of stainless steel as material testing by Ajax indicated this would provide better slip and material transfer than mild steel. In addition, screw geometry was selected with flights that compensate for the angle of operation. To limit the impact of material fallback on effective transfer, each section of the screw conveyor’s covers has a special profile.

Commenting on the project, Johnson Matthey engineering project manager, John Lowe, said: “Initially, we requested Ajax to develop an inclined screw conveyor that would transfer low density powders, at up to 100degC, at a minimum rate whilst deaerating the powder. During the design process alternative thermal expansion joints were required, which Ajax worked closely with us to develop. Ajax then incorporated their designs into our 3D models which provided a useful visual representation of the installation. The meticulously designed equipment ensured perfect installation within the very limited plant space available.”

Following on, Eddie McGee, managing director at Ajax Equipment, commented: “For this project with Johnson Matthey, the design of the screw conveyor and chutes had to fit in with the plant’s current layout and a planned future layout which would introduce a new elevator. Knowing this, Ajax was able to ensure the conveyor’s design would meet the level of productivity required in either layout.”

www.ajax.co.uk

Ajax's inclined screw conveyor installed at Johnson Matthey's Clitheroe plant

« Back

|