20.05.2019

Releasing cohesive material inside silos and pipelines

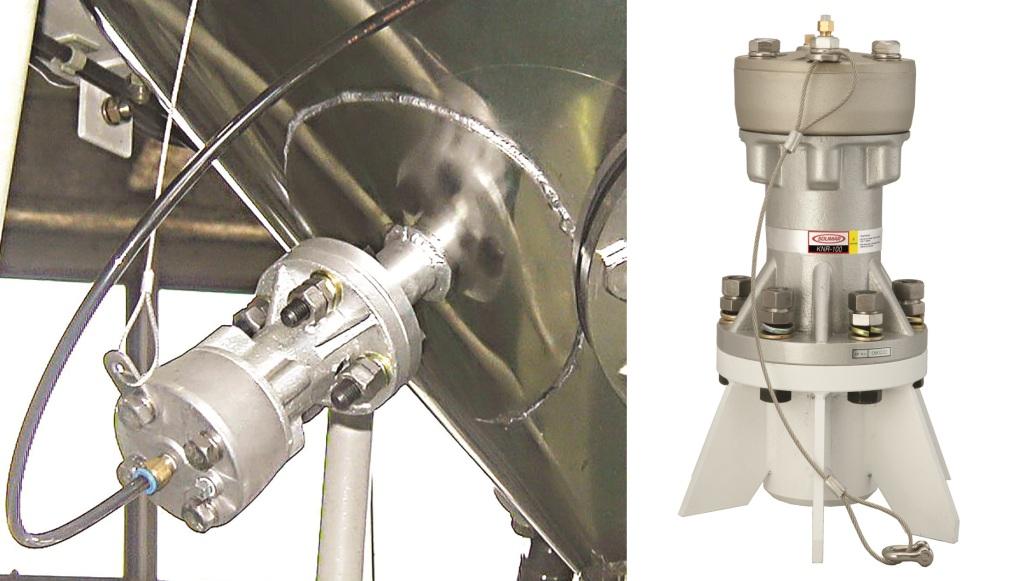

Solimar Pneumatics, Minneapolis, MN, has extended its range of bulk material flow promotion devices with the introduction of the Air Knocker which is designed to keep sticky materials moving even if they are clinging to vessel walls. Novel pneumatic hammering technology loosens the material by the impact of a Knocker piston. The impact pressure can be adjusted to match process objectives and materials. Additional Knockers can readily be added depending on the size and shape of the silo, hopper or piping. A simple design features excellent durability and easy maintenance. Depending on the application, direct or indirect impact models can be specified.

Solimar, whose products – which include the internationally renowned powder fluidizer pads – are available through a network of distributors in most European countries, offers customers free engineering assistance to make the correct choice of model, type of impact and number of Knockers recommended for specific applications which can include: wood pellets, salt, ash, pigments, sand, gravel, saw dust, animal feed, plastic resin, cereal, paper products or any material that is bulky, sticky or becomes stickier with moisture. www.solimarpneumatics.com

Air Knocker from Solimar Pneumatics

« Back

|