06.05.2019

Minimising deterioration of perishable products stored in FIBCs

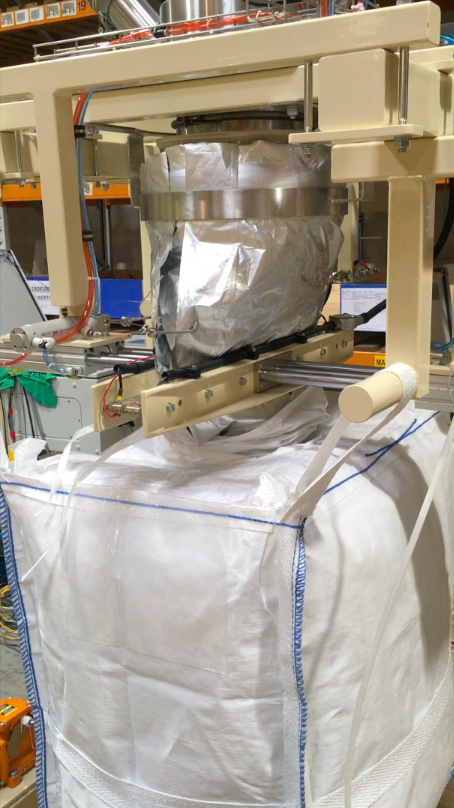

Spiroflow, Clitheroe, UK, is now able to offer customers who use bulk bags the option of inserting foil or plastic inner liners within the woven PP outer bags. Working closely with leading bag liner suppliers, Spiroflow – an internationally respected manufacturer of bulk bag filling stations – has developed technology to integrate these liners, which – following a nitrogen purge and heat sealing process – can significantly extend product shelf life. This innovative solution is expected to be of particular interest to companies involved in bulk handling of nuts, seeds, coffee beans or dried fruits as well as to manufacturers in the pharmaceutical or chemical sectors which could benefit from extended product storage.

Commenting on the initiative, Spiroflow’s James Podevyn, said: “Traditionally when bag filling, the bag would be inflated with air before filling commences. Filling it with nitrogen instead eliminates any oxygen within the bag and after fill the bag can be left inflated or vacuumed, then heat sealed, thereby no air can get in or out.

“The foil or plastic bag liner could be used with any bulk bag filling construction we make and the customer may choose the perfect, bespoke bag for their product, enabling us to build the equipment to meet their exact requirement”.

Spiroflow offers two types of bulk bag fillers. The C Series, for low to medium volume applications, has a modular construction which has the capability to be scaled up from a basic set-up, to be modified when a change in production requirements demands it. The Cone Table Elite (CTE) bulk bag filler has a densification system that can increase bag stability and filling quantity suited to high volume filling or where considerable product consolidation is needed. By increasing the densification, the cost of shipping is reduced as the bags can be filled with more product, thereby increasing cost efficiency. By enhancing the stability of the bags they become safer to handle and to ship, with further potential cost advantages. www.spiroflow.com

A Spiroflow bulk bag filler specially adapted to insert a barrier-proof foil inner liner

« Back

|