15.04.2019

Automatic weighing of minor and micro ingredients

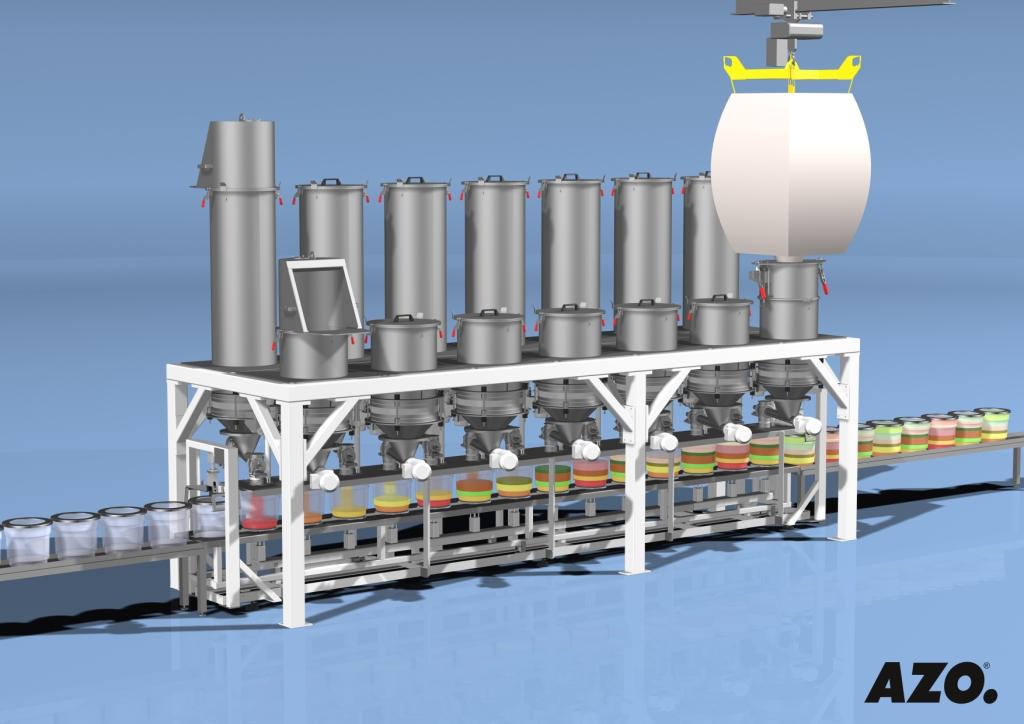

AZO, Osterburken, Germany, has introduced the AZO COMPONENTER® Step. This system makes it possible to weigh ingredients such as flavourings, baking agents, emulsifiers or colourings automatically with gram accuracy. This improves product safety while simultaneously boosting production efficiency by reducing individual manual production steps to a minimum. Especially when it comes to processes requiring stringent hygiene, batch purity and product separation, this latest system enables compliance with strict regulations and specific conditions.

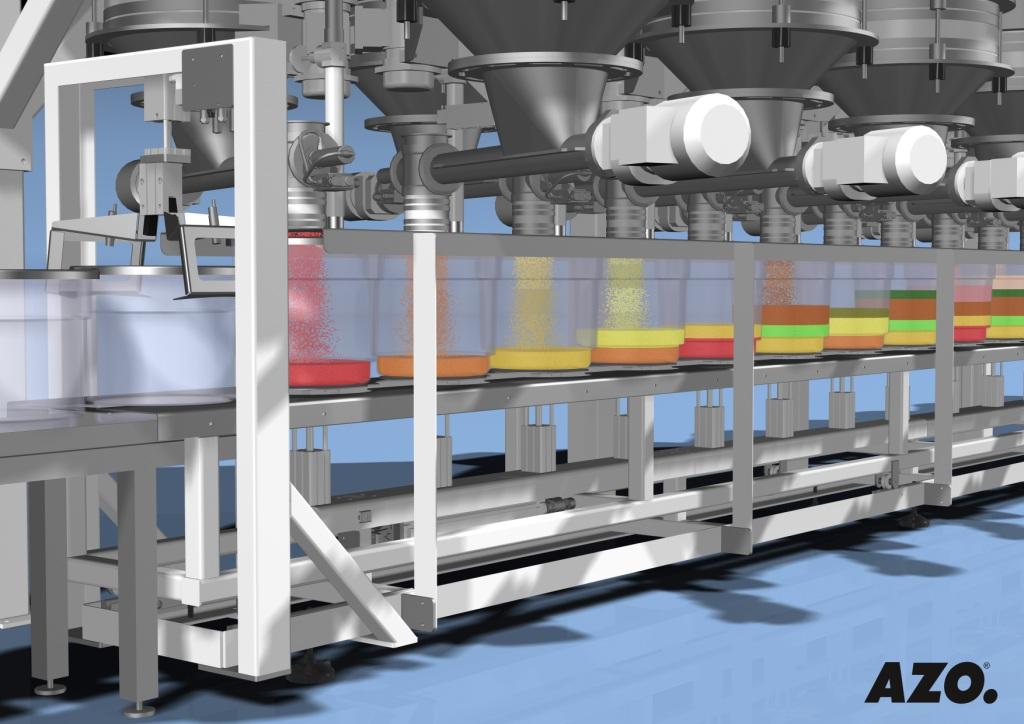

Fully automated filling and transport within a plant result in high throughput rates while achieving considerable levels of accuracy. Tracking and tracing of all raw materials used guarantee maximum product safety. All process steps and weighing results are reproducible, which ensures accurate adherence to recipes. Strict separation of batches prevents risk of cross-contamination. Moreover, thanks to its modular design the system is extremely flexible when it comes to changing products. A high level of hygiene is achieved by having the products filled into receptacles and keeping exposure to dust to a minimum by using aspiration. The outlay for cleaning can be kept low by using storage and target containers for the specific product groups.

The system comprises two levels. The ingredients are held ready in surge bins on the upper level. Prior to filling, the raw materials can be identified using a barcode and allocated to the correct hoppers. This ensures that risk of error is minimised and raw materials can be traced back. The surge bins can be filled from sacks or bulk bags; pneumatic filling is also feasible.

The target containers are processed sequentially on the lower level below the metering points using a hydraulic method of transfer. After dosing in the product quantity specified in the recipe, the target container is transported on to a dosing point.

The target containers are tracked using RFID technology and are thus monitored throughout the entire weighing and metering process. This means that the position, the weighed ingredients and also the allocation of the target containers to a particular recipe are documented and are reproducible. www.azo.com

The automated AZO COMPONENTER Step eliminates risk of human error when it comes to accurate weighing of ingredients

« Back

|