|

|

|

|

| News |

25.02.2019

High performance grinding down to the nano range

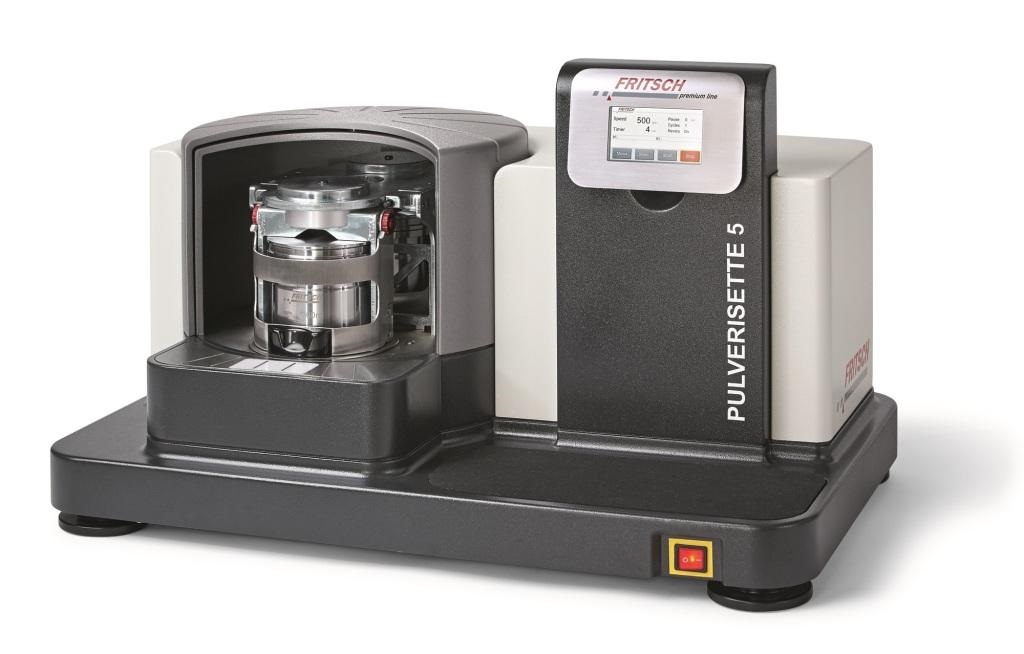

Fritsch Milling and Sizing, Idar-Oberstein, Germany, has introduced the PULVERISETTE 5 Premium Line planetary mill which will be prominently featured on the company’s stand (2-227) at POWTECH. Seen as the ‘big sister’ to the PULVERISETTE 7, this latest model is said to be well suited for fast wet and dry grinding of hard, medium-hard, soft, brittle and moist samples as well as for mechanical alloying, mixing and homogenising with reliable results down into the nano range.

With the brand new ServoLOCK clamping of the grinding bowls and automatic verification that the bowls are safely secured inside the mill, both the operator and the machine are totally protected. In the event of incorrect operation, the machine blocks the start of grinding, and if an imbalance occurs it automatically shuts off. www.fritsch.de

Fritsch’s PULVERISETTE 5 Premium Line, showing (below) safely guided insertion of the grinding bowl

« Back

|

|

|

|

|

|

|

|

Copyright © 2015 Oakhill Media Ltd. All rights reserved.

|