25.02.2019

Third IRD helps expand production of food packaging for KP Linpac in Germany

Kreyenborg, Senden, Germany, recently won an order to supply an Infrared Rotary Drum (IRD) to the new Beeskow plant of KP Linpac. This is the third Kreyenborg IRD to be installed at KP Linpac sites in Germany, the previous two going to the company’s Ritterhude plant.

IRDs offer the capability to crystallise and dry varying PET input materials quickly and in a single process. In Germany, KP Linpac produces PET sheet and, in a second step, thermoformed trays for foodstuffs at both its company sites. In this activity, the plastics producer attaches importance to the conservation of natural resources, flexibility and efficiency. These are precisely the benefits offered by the Infrared Rotary Drum made by Kreyenborg.

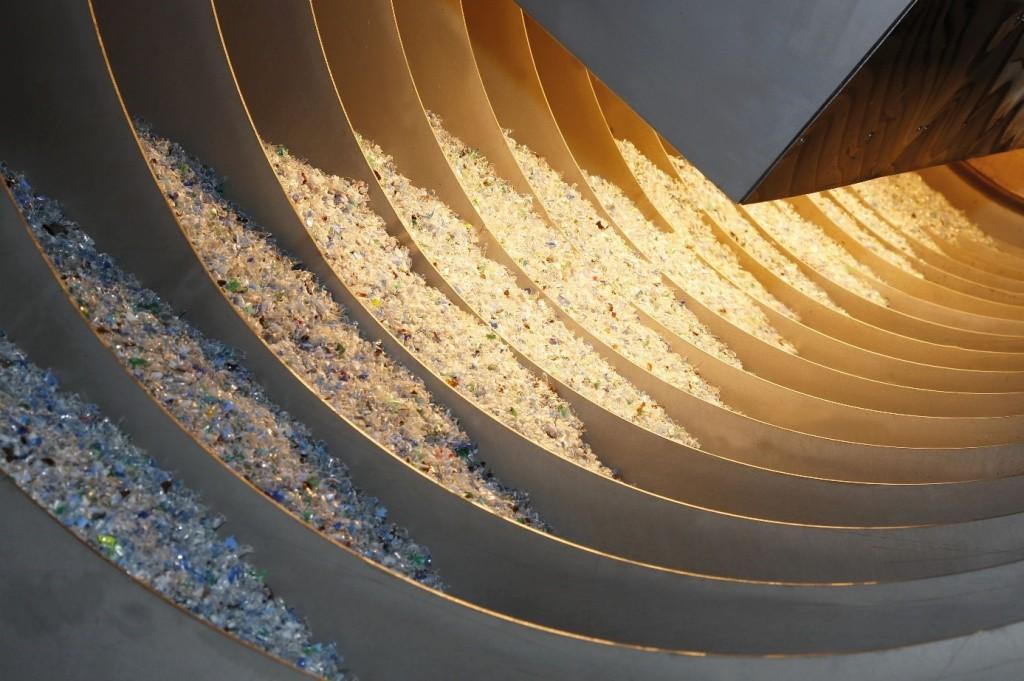

An IRD for KP Linpac achieves a continuous drying capacity of 800kg/h. Here the material fed in is circulated and conveyed on a permanent basis thanks to the rotary movement of the tube. “The low filling level in combination with the high circulating speed make the IRD a very efficient crystallisation and drying unit, which not only works more quickly than ordinary desiccant air dryers, but also needs less energy and is much more flexible as regards the materials used,” explained the project manager in charge at Kreyenborg, Marcus Vogt. For KP Linpac ‘flexibility’ means that it can process not only ground punching scrap, but also edge trims from sheet production and variable mixtures from both of them. Infrared light ensures material heating in the IRD, virtually from inside out. In this way, a crystallisation effect is achieved at roughly 135°C in the first step and material drying is achieved at around 170°C in the second step. www.kreyenborg.com

Thanks to the rotary movement of Kreyenborg’s IRD tube, combined with the low filling level, material is in a permanent state of being circulated and conveyed

« Back

|