18.02.2019

Lump breaker reduces agglomerates down to 2mm particles

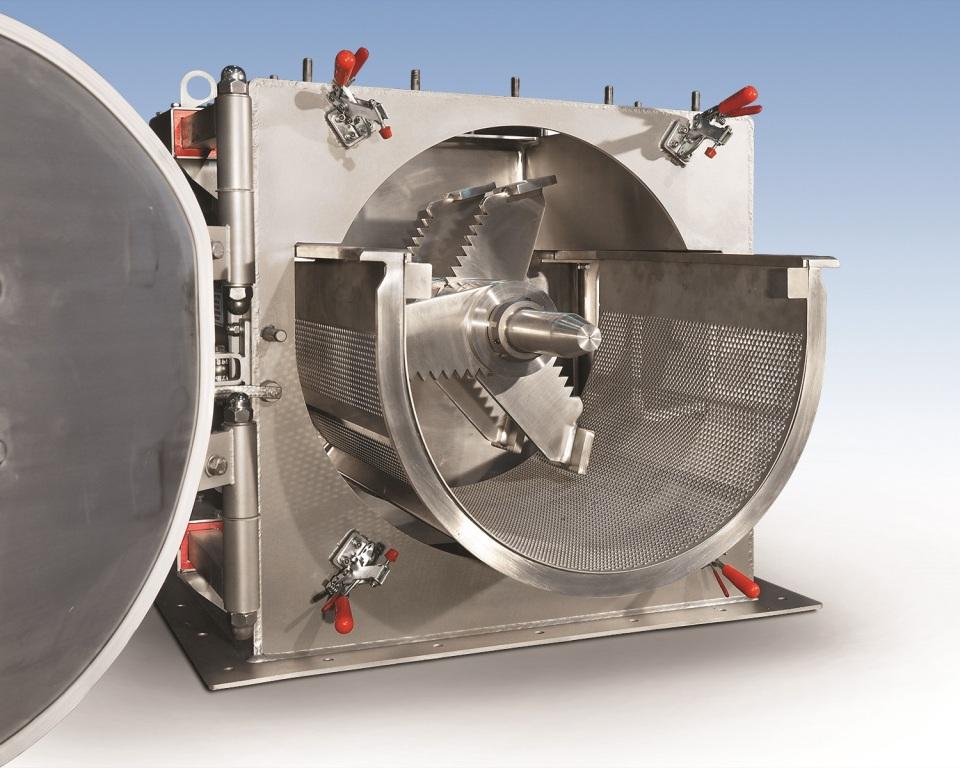

Kason Europe, Stoke-on-Trent, UK, has introduced the model LB 550 lump breaker which has been designed and manufactured by its US parent company. It is capable of reducing agglomerates as large as 250mm into particles with an average size as small as 2mm with minimal heat generation or fines at rates from 2 to 25t/h.

Material is gravity fed through an upper intake port and whisked against a contoured grinding screen by serrated blades projecting from a rotating shaft, driven at low speeds by a high-torque gear-reduced motor. On-size particles pass through the screen and fall through a discharge chute, while oversize particles remain in the milling chamber until reduced sufficiently to pass through the screen.

Available in carbon steel, 304 or 316 stainless steel, Hastelloy and other alloys, it features interchangeable rotors and easy-to-change grinding screens mounted on a pull-out cradle. Screens are offered with round, square or rectangular apertures from 2 to 75mm, and with raised ‘cheese grater’ lips to suit a wide range of process requirements.

The LB 550 is available constructed to pharmaceutical, food and industrial standards, and in ATEX compliant models for use in potentially explosive atmospheres up to and including ATEX21 internally and externally. www.kasoneurope.com

The Kason LB 550 lump breaker can reduce agglomerates to particles as small as 2mm; serated blades (below) projecting from a rotating shaft whisk material against a contoured grinding screen

« Back

|